The highest power level for a powder actuated device is a crucial aspect that influences its performance and safety. This article delves into the intricacies of this topic, exploring the industry regulations, device design considerations, applications, safety precautions, and future innovations that shape the development and use of high-power powder actuated devices.

The discussion provides valuable insights into the factors that determine the maximum power level achievable, the advantages and disadvantages of using high-power devices, and the essential safety measures that must be adhered to. By understanding these aspects, professionals can make informed decisions when selecting and operating powder actuated devices, ensuring optimal performance and minimizing risks.

1. Safety Regulations

The highest power level for a powder actuated device is subject to strict industry standards and regulations. These regulations aim to ensure the safe operation and handling of these devices by establishing limits on the maximum power output they can produce.

The rationale behind these regulations is to minimize the risk of accidents and injuries. High-power powder actuated devices can generate significant recoil and produce potentially hazardous debris, so it is crucial to control their power output to prevent harm to users and bystanders.

Specific regulations governing the power level of powder actuated devices vary depending on the jurisdiction. However, common requirements include:

- Limiting the maximum powder charge size

- Specifying minimum barrel length requirements

- Requiring the use of safety features such as recoil compensators and debris shields

Enforcement of these regulations is typically carried out by government agencies responsible for occupational safety and health. Inspections, audits, and certification processes are used to ensure compliance with the established standards.

2. Device Design Considerations

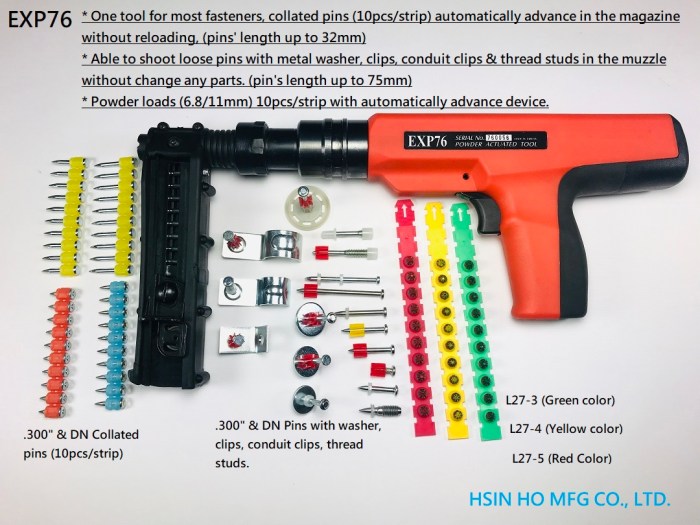

The power level of a powder actuated device is influenced by several design factors:

Cartridge Size

The size of the powder cartridge determines the amount of propellant it contains. Larger cartridges produce higher power levels.

Propellant Type, The highest power level for a powder actuated device is

Different types of propellants have varying energy densities. High-energy propellants generate higher power levels.

Barrel Length

The length of the barrel affects the pressure buildup and the velocity of the projectile. Longer barrels allow for more propellant combustion and higher power levels.

These factors interact to determine the maximum power level achievable by a powder actuated device. Designers must carefully balance these factors to meet specific application requirements while adhering to safety regulations.

3. Applications and Limitations: The Highest Power Level For A Powder Actuated Device Is

Powder actuated devices with the highest power levels are commonly used in applications where maximum penetration and force are required:

- Driving fasteners into concrete or steel

- Demolition and construction work

- Mining and tunneling operations

Advantages of using high-power devices include:

- Increased penetration depth

- Faster and more efficient fastening

- Ability to handle tough materials

However, disadvantages include:

- Higher recoil forces

- Increased risk of debris projection

- Limited maneuverability due to larger size and weight

Careful consideration of the application requirements and limitations is essential when selecting a powder actuated device with the highest power level.

4. Safety Precautions and Training

Using powder actuated devices with the highest power level requires strict adherence to safety precautions:

- Wear appropriate personal protective equipment (PPE), including eye and hearing protection

- Secure the work area and ensure proper ventilation

- Follow manufacturer’s instructions for loading and firing the device

- Never point the device at anyone or anything other than the intended target

Proper training and certification are crucial for operators of high-power powder actuated devices. Training programs should cover:

- Safety regulations and operating procedures

- Device maintenance and troubleshooting

- Emergency response protocols

Regular refresher training and adherence to safety guidelines are essential to minimize risks and ensure safe operation.

5. Future Developments and Innovations

Emerging technologies and innovations may lead to higher power levels for powder actuated devices in the future:

- Advanced propellants with higher energy densities

- Improved barrel designs for increased pressure containment

- Electronic control systems for precise power level adjustment

These developments have the potential to enhance the capabilities and efficiency of powder actuated devices while maintaining safety.

However, it is important to note that advancements must be balanced with adherence to safety regulations and industry standards to ensure the responsible and safe use of high-power powder actuated devices.

FAQ Summary

What factors influence the power level of powder actuated devices?

The power level of powder actuated devices is influenced by factors such as cartridge size, propellant type, and barrel length. These factors interact to determine the maximum power level achievable.

What are the advantages of using high-power powder actuated devices?

High-power powder actuated devices offer advantages such as increased penetration depth, ability to drive fasteners into harder materials, and improved productivity in demanding applications.

What safety precautions must be taken when using high-power powder actuated devices?

When using high-power powder actuated devices, it is essential to adhere to safety precautions such as wearing appropriate personal protective equipment, ensuring proper ventilation, and maintaining a safe working distance.